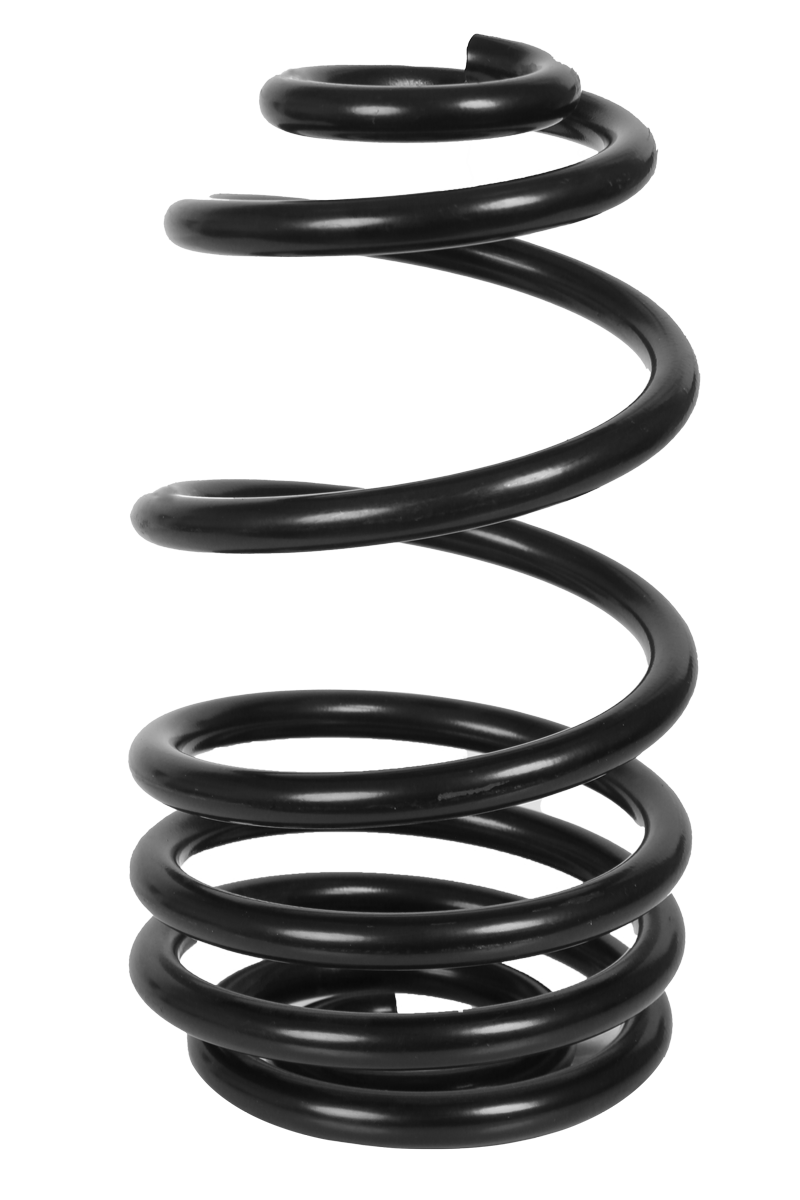

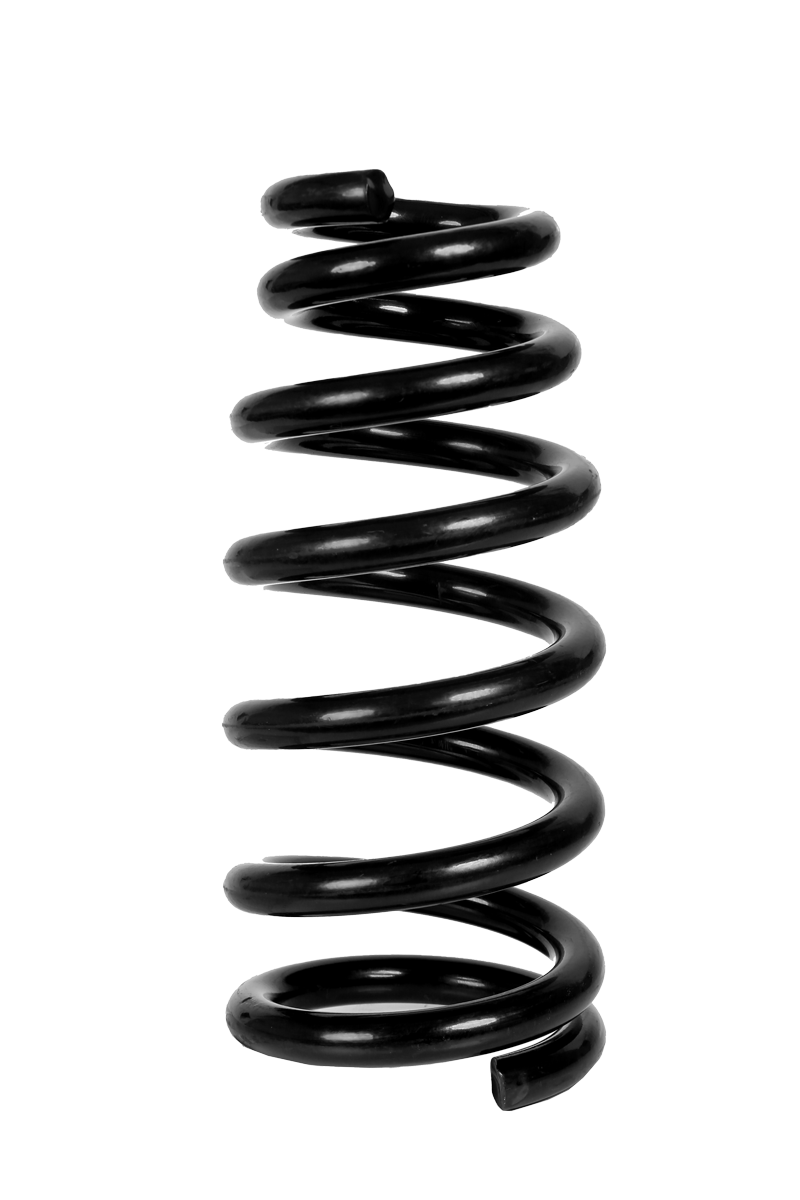

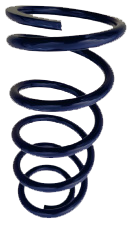

Nanyang Tongdao Spring Co., Ltd. is an export-oriented enterprise specializing in the production of automotive suspension springs, and is a professional spring R&D and production solution provider in China. The company was established in 2018, covering an area of 25000 square meters, with a powerful and highly efficient production team. The company integrates research and development, production, and sales, and its products are mainly sold to Europe, North America, Russia, and other regions and countries.

The company has a complete set of suspension spring production equipment, including a steel wire drawing and oil quenching production line, five precision spring production lines, and a variable diameter spring production line. It also has full process materials and product inspection and testing equipment and facilities. It has 95% of global vehicle model data, with sample data reaching 15000 SKUs. The company has passed IATF16949:2016.

Tongdao Spring has established a business philosophy of "quality first, service foremost" since the establishment of the factory, striving to provide customers with a satisfactory experience of quality+service.

In order to ensure controllable risk, stable product quality and satisfactory service for customers, Tongdao Spring has established the management concept of safety, specialization, refinement and datafication.

Tongdao Spring always regards the talent team as the first resource and wealth. Respect, cherish, and cultivate employees.